عنا

مرحبا هل يمكنني مساعدتك؟

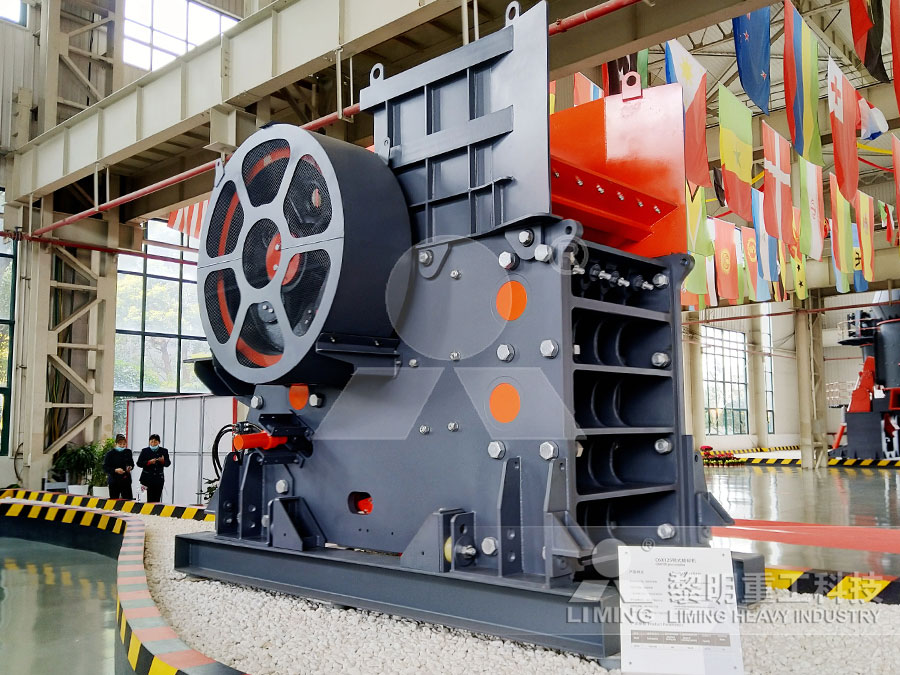

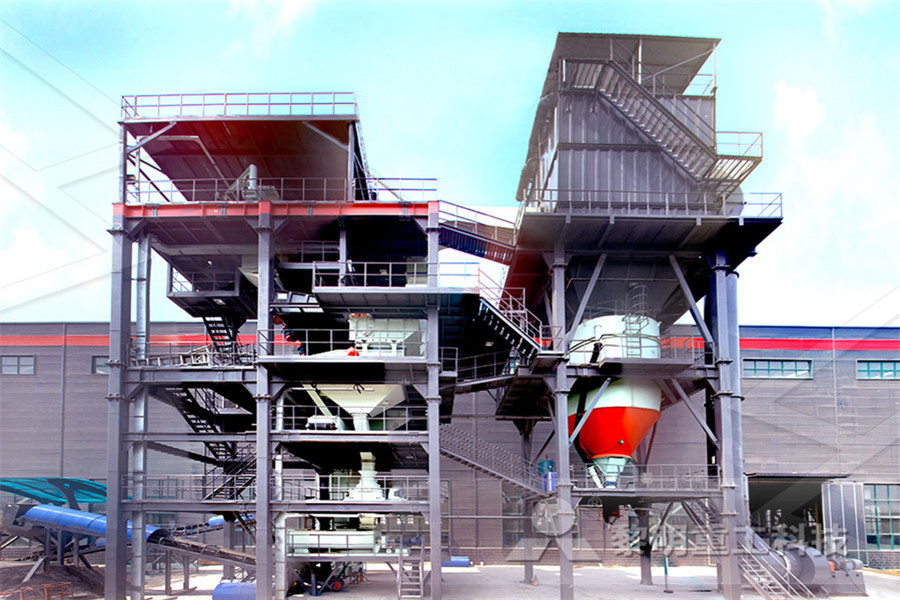

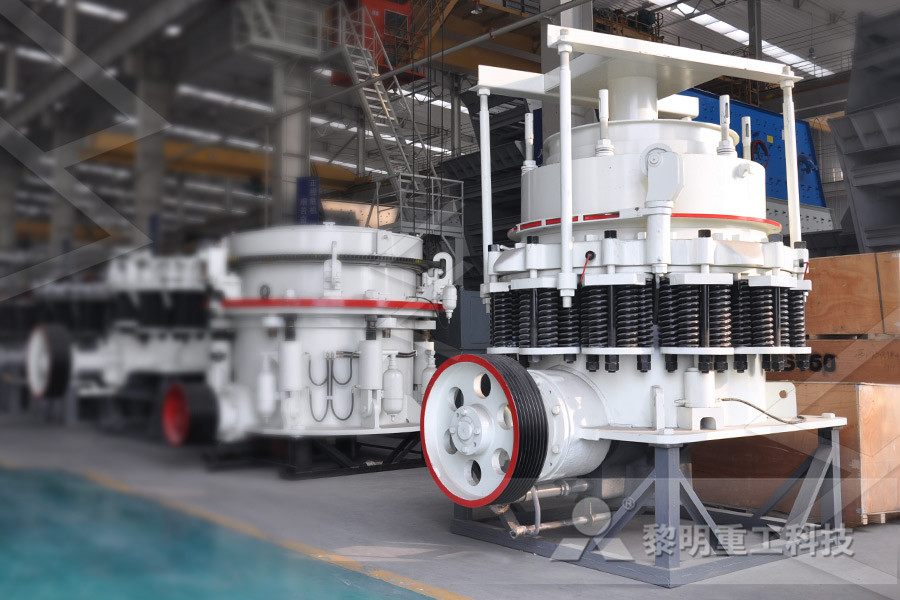

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding mills beads

2022-02-18T22:02:52+00:00

Grinding/Milling/Dispersing Grinding Beads Ceramic Beads

The grinding beads should be 2 – 3 times larger than the separator or filter of the mill (eg slotted sieve, sieve cartridge, friction gap) The grinding media should be at least 5 times With over 90 years of experience, we have established a profound expertise and a broad customer base in almost every application in the wet grinding and dispersing industry Bead Mills Grinding and Dispersing Group2016年11月1日 Ceramic bead behavior in ultra fine grinding mills ScienceDirect Minerals Engineering Volume 98, November 2016, Pages 232239 Ceramic bead behavior in ultra Ceramic bead behavior in ultra fine grinding mills

DYNO®MILL bead mills and grinding beads

The DYNO®MILL UBM grinding mills can grind with beads from 03 to 25 mm Ideal for very fine grinding of large volumes of product Suitable for grinding in recirculation and in passage mode Send us an email for A wide range of grinding media The quality of your grinding media significantly influences the performance and durability of your bead mill We can help you select the right Grinding Media for Bead Mills Grinding and Dispersing2016年11月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed Ceramic bead behavior in ultra fine grinding mills

耐驰球磨机 SpheRho 耐驰研磨分散

2021年2月8日 NETZSCH Dry Agitator Bead Mill SpheRho ® Brochure NETZSCH Labsized Dry Agitator Bead Mill SpheRho ® Brochure NETZSCH FineGrinding and Fine 2021年2月8日 产品 解决方案 干法研磨 Pamir 干法搅拌球磨 应用于矿物和陶瓷原材料的干法研磨,耐驰 Pamir 在高产品细度,高产出率,低能耗上让人印象深刻。 数十年了, Pamir 干法搅拌球磨 耐驰研磨分散The DYNO®MILL UBM grinding mills can grind with beads from 03 to 25 mm Ideal for very fine grinding of large volumes of product Suitable for grinding in recirculation and in passage mode Send us an email for DYNO®MILL bead mills and grinding beads

Performance Comparison of the Vertical and Horizontal

2023年2月23日 noticeably different [6] The Tower Mills can cope with 6 mm top size; hence, it should utilize coarser balls inside the chamber Therefore, the comparisons of the two mills may not be appropriate for fine grinding range The study held by Parry [18] compared SMD technology and horizontal stirred media mill, called Netzsch mill The test SiLibeads® glass beads have been and continue to be used as grinding or dispersing beads, either as a costeffective alternative to more expensive ceramic beads or for performance reasons in older, less powerful mills SiLibeads® glass beads are also used for grinding sensitive grinding materials for which ceramic beads cannot or may not be Grinding/Milling/Dispersing Glass Beads SiLi2016年11月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Ceramic bead behavior in ultra fine grinding mills

FRANLI wet grinding, dispersing mixing manufacturer

About Franli Franli is a market leader in a onestep smart coating, adhesive, and Agrochemistry solution company, processional focus on chemical machines in China for 20 years Franli mainly produces Bead mills , Three Roll Mill , Twin Shaft Disperser , High Speed Disperser , High Shear Mixer , Double Planetary Mixer, Paint Filling Machine 2019年8月1日 The grinding limit or minimum particle size can be calculated from intercrystalline material parameters as described by Knieke et al [55]The compression strength σ CS is a material parameter, and was used based on the assumption that compression is the dominant type of stress in a stirred media mill The compression strength and Mill, material, and process parameters ScienceDirect2023年11月5日 They are used in all mill types and are particularly suited to high energy and recirculation processes YttriaStabilized Zirconia SaintGobain premium grade milling beads ensure the best control of the grinding process of inorganic materials, with the absence of breakage and low contamination of the final product, as required in highend Yttria Stabilized Zirconia Beads Zirpro

Optimisation and analysis of bead milling process for preparation

2018年6月1日 Generally, high viscosity dispersions are not easy to grind using a labscale recirculating bead mill There are numerous factors that can potentially result in changes in the starting point formulations The size of zirconium oxide beads used as grinding media was between 1 and 125 mm and the bead loading was maintained between 30 and 35 Products that are difficult to shred: Larger grinding media are more effective The grinding beads should be 2 – 3 times larger than the separator or filter of the mill (eg slotted sieve, sieve cartridge, friction gap) The grinding media should be at least 5 times smaller than the distance between agitator disc and grinding vessel wallGrinding/Milling/Dispersing Grinding Beads Ceramic Beads 2012年6月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Effect of the size of media on grinding performance in stirred mills

Stirred media mills in the mining industry: Material

2020年6月1日 Motion and stress intensity of grinding beads in a stirred media mill Part 1: Energy distribution and motion of single grinding beads Powder Technol , 86 ( 1996 ) , pp 59 68 , 101016/00325910(95)0303871 天前 The Perfect Grind Starts with the Perfect Grinding Media Whatever you are grinding, in a ball mill or bead mill, you’ll find the right grinding beads for the job, here at FOX What applications can you use FOX Grinding Media for? From Albania to Zimbabwe, and everywhere in between, FOX grinding beads are used as milling media for the Milling Media Ball Mill Grinding Media FOX Industries2023年11月5日 ER120 The original ceramic bead ER120 is a fused ceramic grinding bead based on zirconium silicate Available in two grades, ER120A is well suited to large volumes and vertical mills, while ER120S Zirconium Silicate Beads Zirpro

Assessing the influence of viscosity and milling bead size on

2018年8月1日 In bead mills colliding grinding media are used to stress the product In stirred media mills the beads are agitated by an externally driven stirrer In general, mills are characterized by the type of stressing, the transferred energy per stress event (stress energy SE) and the number of stress events (stress number SN)2018年8月1日 In bead mills colliding grinding media are used to stress the product In stirred media mills the beads are agitated by an externally driven stirrer In general, mills are characterized by the type of stressing, the transferred energy per stress event (stress energy SE) and the number of stress events (stress number SN) Assessing the influence of viscosity and milling bead size on 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s Energy Use of Fine Grinding in Mineral Processing SpringerLink

EnergyEfficient Advanced Ultrafine Grinding of Particles

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material Various models of bead mills from FRANLI A horizontal sand mill is a highefficiency wet ultrafine grinding and dispersing machine widely used in nonmetallic mineral industries such as coatings, dyes, paints, inks, medicine, magnetic powder, ferrite, photosensitive films, pesticides, papermaking, and cosmetics Sand Mill Franli MachineGrinding Bead found in: Bulk Beads and Prefilled Kits, Soil grinding SK38, 7mL, Grinding Beads for Geno/Grinder, Stainless Steel Beads, Lysing Matrix S, 96 is an extremely versatile bead mill homogenizer that has applications in a variety of areas, including biological research, environmental testing, and industrial settings Adapters are Grinding Bead at Thomas Scientific

Grinding Media Union Process

Alumina Balls and Satellites Union Process is the one source for 90%, 94%, 995% and 999% alumina media 90% alumina is available in satellites and rod/cylinders 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination They have great wear rate generally better than 90% or 99 2023年11月5日 Jar mills are excellent for grinding virtually any type of sample Analytical and hand mills are ideal for hard and brittle samples Lab bead mills are used for cell and tissue culture pr MORE + 53 RESULTS Lab Mills Grinding Mills, Jar Mills, Accessories2021年3月15日 The mill body is surrounded by a cooling jacket to cope with the challenges of dry grinding where the temperature is an issue due to the cohesiveness of the particles to the walls and the beads There exist several instruments measuring the power, temperature, pressure and air flow rates of the mill and the grinding plantImpacts of process and design conditions of dry stirred

Optimization of operating conditions on ultrafine coal grinding

2022年5月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the least ’s bead mills cover almost every wet grinding and dispersing application, tailored to customer requirements Solutions Food, feed confectionery From fullvolume up to highenergy bead mills, we set the technology standards for efficient, sustainable wet grinding processes + Product range Explore our range of bead millsBead Mills Grinding and Dispersing Group2023年11月3日 The closed horizontal agitator bead mill is designed for the highest product throughput rates and has a peg grinding system with extremely high grinding intensity The Zeta ® grinding system is, in every respect, a user friendly, lowmaintenance and very reliable grinding system Starting with the structural design of the agitator mill, there Grinding System Zeta® NETZSCH Grinding Dispersing

EnergyModel and Life CycleModel for Grinding

2022年5月23日 The production of fine and ultrafine limestone particles in grinding mills has an important role for the development of future products Limestone as grinding material is used in Guner et al [11], the effect of stirrer speed and bead material filling ratio on particle break were examined during wet stirred media grinding using kinetic 2021年2月11日 proach of two grinding beads into account, a lubrication force between grinding beads was implemented as described in [28] The DEM was extended to track bead–bead contacts The geometry of the laboratory mill with disc stirrer geometry (PM1, Drais/, see Figure1a) consisted of a rotor shaft (r sh = 15 mm) with discs (R = 36 Grinding Media Motion and Collisions in Different Zones 2021年9月1日 Dry agitated bead mill The mill design is based on the wetoperated LMZ bead mill series by NETZSCH Feinmahltechnik GmbH The dry development called SpeRho was led by NETZSCH Trockenmahltechnik GmbH As shown in Fig 1, it is a horizontally operated mill with a grinding vessel and a shaft equipped with agitatorsGeometry influence on optimized operation of a dry agitator bead mill

Study on the Effects of Grinding Factor and Scaling up in

principle, bead mill is greatly expected to be used to fulfil today’s industry’s needs which demands various milling operation Because, bead mills can provide grinding conditions under a high packing density and high energy density of the media as well as cover a broad range of output (Tanaka, 1994) However, because of itscompositionshort2012年6月1日 Fig 6 (b) shows the variations of the grinding rates with medium size at different rotation speeds It indicates that grinding using 4 mm glass beads is slightly faster at 800 rpm and 1600 rpm than using 2 mm or 6 mm glass beads However, the grinding rate slightly decreases with increasing medium size at 1200 rpmEffect of the size of media on grinding performance in stirred mills 2019年7月19日 A stirred bead grinding mill includes a substantially cylindrical grinding shell and a central stirring shaft within the grinding shell The central stirring shaft is provided with axially spaced stirring elements, preferably grinding discs, along the central stirring shaft A replaceable grinding element is provided that includes an axial support structure Stirred bead grinding mills Justia Patents

Regrinding and fine grinding technology the facts and

2016年6月3日 In the gap between the tip of the stirrer disc and the mill wall, grinding beads move in circular rings of different circumferential velocities Figure 2 shows that these relative velocities decrease with increasing radius Figure 2 Relative circuferential grinding bead velocity on a stirrer disc (Theuerkauf and Schwedes, 1999)2 天之前 Agitator bead mills are grinding machines for ultrafine processing of solids in liquids Their area of application covers the particle size range from 200 μm (max 500 μm) down to the submicron (nanometer) range With a comminution factor down to 1 : 10 000 (200 μm > 20 nm), the application range is extensive and the variety of tasks Solutions in the field of Wet Grinding2021年4月29日 The grinding media make the difference The quality of the grinding media significantly influences the performance and durability of a bead mill Selecting the right grinding media is therefore decisive for the product quality and Process stability High product quality thanks to a stable wetgrinding process Maximum durabilityCeramic grinding media for bead mills

Experimental assessment of grinding bead velocity

2021年1月8日 Radiometric methods detect the local filling degree, but little is known about the experimental motion of the grinding beads in the mill This study aims to investigate the position, velocity and 1999年11月11日 to the orientation as horizontal or vertical bead mills The stirrer usually consists of a shaft fitted with either discs or pins, and in addition there may be stator pins Previous literature [13] describes the main principles of fine grinding in stirred bead mills The grinding mechanism occurs due to fine particles being trapped andCFD MODELLING OF A STIRRED BEAD MILL FOR FINE Application VOLLRATHbeadmills type VMSM are used for wet grinding of suspensions and pigment pastes They are well proven and widely used in the paint and coatings industries The bead mill belongs to the family of agitatormills and agitatorballmills In the wet grinding of paints and varnishes, the classic ball mill has been completely BeadMills Vollrath GmbH

Grinding Dispersion Technology WAB Willy A Bachofen

Wet grinding technology focuses on the controlled real size reduction, dispersion and deagglomeration of solid particles in a liquid medium Particle finenesses in the micro to nanometer range can be achieved For more than 60 years, WABGROUP has focused on the invention and further development of closed horizontal agitator bead mills1 This bead mills are batch process machine for size reduction and dispersing of paints, inks, coatings etc The bead mills are widely used in labs for processing of small daily batches The bead mill consists of a grinding vessel inside which rotates a shaft fitted with impeller disc The grinding media and the charged material are filled Mild Steel Bead Mills Exporter from Chennai GrindingThe DYNO®MILL UBM grinding mills can grind with beads from 03 to 25 mm Ideal for very fine grinding of large volumes of product Suitable for grinding in recirculation and in passage mode Send us an email for DYNO®MILL bead mills and grinding beads

Performance Comparison of the Vertical and Horizontal

2023年2月23日 noticeably different [6] The Tower Mills can cope with 6 mm top size; hence, it should utilize coarser balls inside the chamber Therefore, the comparisons of the two mills may not be appropriate for fine grinding range The study held by Parry [18] compared SMD technology and horizontal stirred media mill, called Netzsch mill The test SiLibeads® glass beads have been and continue to be used as grinding or dispersing beads, either as a costeffective alternative to more expensive ceramic beads or for performance reasons in older, less powerful mills SiLibeads® glass beads are also used for grinding sensitive grinding materials for which ceramic beads cannot or may not be Grinding/Milling/Dispersing Glass Beads SiLi2016年11月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Ceramic bead behavior in ultra fine grinding mills

FRANLI wet grinding, dispersing mixing manufacturer

About Franli Franli is a market leader in a onestep smart coating, adhesive, and Agrochemistry solution company, processional focus on chemical machines in China for 20 years Franli mainly produces Bead mills , Three Roll Mill , Twin Shaft Disperser , High Speed Disperser , High Shear Mixer , Double Planetary Mixer, Paint Filling Machine 2019年8月1日 The grinding limit or minimum particle size can be calculated from intercrystalline material parameters as described by Knieke et al [55]The compression strength σ CS is a material parameter, and was used based on the assumption that compression is the dominant type of stress in a stirred media mill The compression strength and Mill, material, and process parameters ScienceDirect2023年11月5日 They are used in all mill types and are particularly suited to high energy and recirculation processes YttriaStabilized Zirconia SaintGobain premium grade milling beads ensure the best control of the grinding process of inorganic materials, with the absence of breakage and low contamination of the final product, as required in highend Yttria Stabilized Zirconia Beads Zirpro

Optimisation and analysis of bead milling process for preparation

2018年6月1日 Generally, high viscosity dispersions are not easy to grind using a labscale recirculating bead mill There are numerous factors that can potentially result in changes in the starting point formulations The size of zirconium oxide beads used as grinding media was between 1 and 125 mm and the bead loading was maintained between 30 and 35 Products that are difficult to shred: Larger grinding media are more effective The grinding beads should be 2 – 3 times larger than the separator or filter of the mill (eg slotted sieve, sieve cartridge, friction gap) The grinding media should be at least 5 times smaller than the distance between agitator disc and grinding vessel wallGrinding/Milling/Dispersing Grinding Beads Ceramic Beads 2012年6月1日 This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the Effect of the size of media on grinding performance in stirred mills