عنا

مرحبا هل يمكنني مساعدتك؟

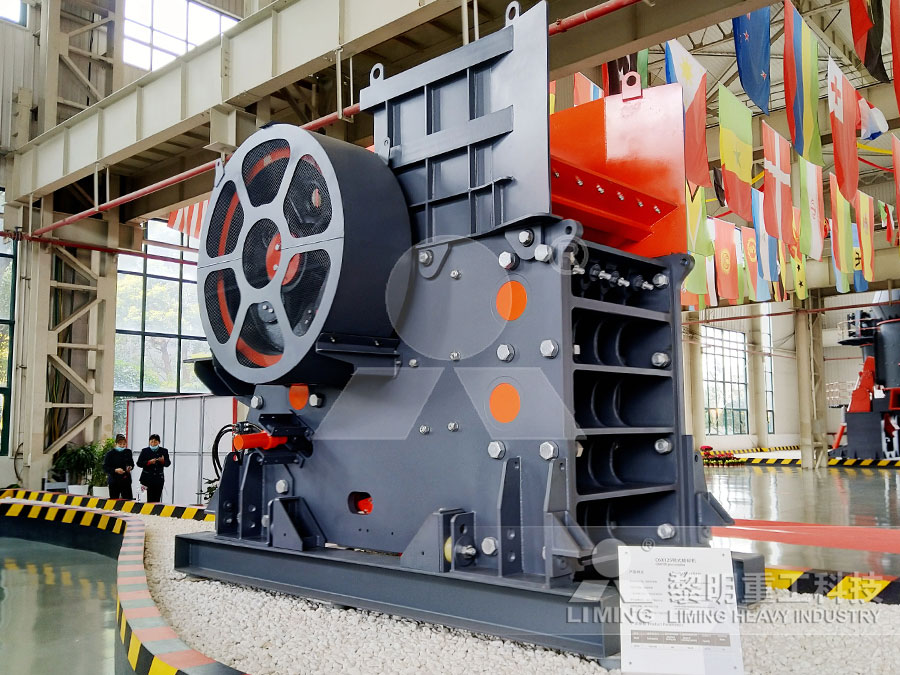

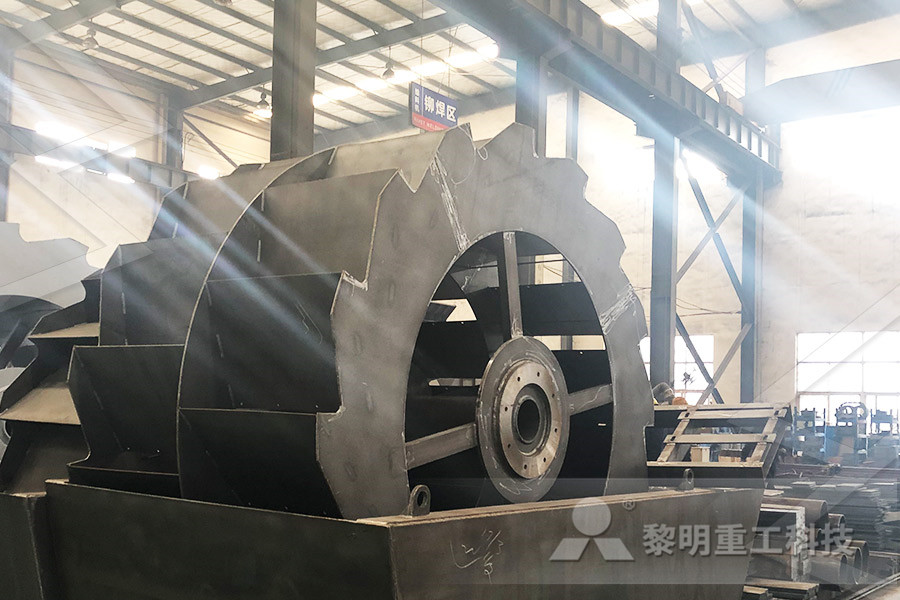

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

used mm rolling mill

2023-07-23T00:07:53+00:00

Used Metal Rolling for sale in China Machinio

Used Metal Rolling for sale in China Machinio Your location: Boydton, Virginia, US USD ($) Sell on Machinio Testimonials Sign In Machinio CATEGORIES Machine Tools » Metal China Used Rolling Mill manufacturers Select 2023 high quality Used Rolling Mill products in best price from certified Chinese Copper Rod, Foil Rolling Mill suppliers, wholesalers China Used Rolling Mill, Used Rolling Mill Manufacturers, Suppliers 2020年3月8日 Alibaba offers 1,189 used rolling mill for sale products such as new, used You can also choose from manufacturing plant, building material shops, and Used Rolling Mill For Sale China Trade,Buy China Direct From Used

rolling mill used machine for sale

Robust fine rolling mill with 800 mm roll width and 800 mm roll diameter, incl main drives, auxiliary drives, control cabinet and hydraulic unit for splitting In regularly maintained Robust fine rolling mill with 800 mm roll width and 800 mm roll diameter, incl main drives, auxiliary drives, control cabinet and hydraulic unit for splitting In regularly maintained steel rolling used machine for sale for used rolling mills Find Ruesch, Danieli, Ross, SMS Eumuco, Schmitz, Mannesmann Demag Meer, and Meco for sale on Machinio Used Rolling Mills for saleUsed Rolling Mills for sale Ruesch equipment more

China Second Hand Rolling Mill, Second Hand Rolling Mill Manufacturers

Second Hand Cold Rolling Mill and Used Tension Leverler US$ / Piece 1 Piece (MOQ) Customized : Customized; Condition : New; Power Source : Electric; Get the best deals on Rolling Mill when you shop the largest online selection at eBay Free shipping on many items Browse your favorite brands affordable pricesRolling Mill for sale eBayUsed Rolling Mills machinery for sale If you're looking for used Rolling Mills machines, Machine Hub is the marketplace for you Get free quotes from our vast network of used Rolling Mills Used Machines Machine Hub

Used Forging Ring Mills for sale Wagner equipment more

3,500mm Asian Built Radial Axial Ring Rolling Mill Re:24925 used Manufacturer: Asian Built; Dia: 3,500 mm Height: 800 mm Builder: Asian Built Radial: 280 tonnes Axial: 7,810 km Thread rolling machine FETTE R 40 (12 39 mm) Gewinderollkopf Fette 1980 used €5,500 Fixed price plus VAT Send inquiry Thread rolling machine make FETTE type R 40 Make # 818 Year of manufacture 1980 Technical data: Thread rolling range metric 12 39 mm thread rolling range inch 7/16 1 1/2" gr rolling thread length 500 mm Used Rolling Mills for sale on Machineseeker2013年5月30日 Fig 4 Roll configurations in rolling mills Twohigh mill roll configuration – This is the most commonly used rolling mill configuration In this configuration, there are two horizontally mounted rolls The rolling Basics of Rolling and Rolling Mills – IspatGuru

A Comparative Analysis of Forming Railway Axles in 3 and 4Roll

2020年7月10日 The currently biggest 2roll rolling mills of D461500 type have 1500 mm diameter rolls and make it possible to produce Ø 160 mm × 1300 mm parts In turn, the biggest flatwedge rolling mills, WRL20035TS, have 35 m long tools and make it possible to roll parts of up to Ø 200 mm × 1200 mm in size In effect, the CWR machines are not 2023年3月31日 The 5500 mm thick plate rolling mill studied in this paper adopts the bottom installation, as shown in Figure 2 and Figure 3, the HGC hydraulic cylinder is installed on the bottom of the frame, and above it is the lower support roll, the lower work roll, the upper work roll, and the upper work roll The roll gap of a rolling mill generally Biomimetics Free FullText Optimization Strategy of Rolling Mill TwoHigh: Generally, a 2HI mill is used for hot or cold breakdown and finishing of bar, sheet or strip A wide range of sizes with separating force capacities from 10,000 lbs (453 MT) to over 3,000,000 lbs (1360 MT) are available ThreeHigh: A 3HI mill is an economic milling solution for the breakdown of rod and ingot FourHigh: A 4HI mill may be used for finish Rolling Mills Metal Rolling Mill Machine Rolling Mill

(PDF) Wear of hot rolling mill rolls: an overview ResearchGate

1994年8月1日 tons of hot rolled steel per millimetre of machined roll diameter (t/mm), whereas typical flat rolls have "lives" about 5 10 320 10 3 t/mm blockondisc and laboratory hot rolling mill2020年6月1日 Abstract and Figures This work deals with the simulation model of multimachines system as cold rolling mill is considered as application Drivers of rolling system are a set of DC motors, which (PDF) Simulation Model of Cold Rolling Mill ResearchGate2020年1月3日 The rolling mill produces sections with diameters from 90 mm to 200 mm Traditional technology does not provide opportunity for rolling the sections with diameters of more than 200 mm In (PDF) 2020 Technology and Operation of a Hot Rolling Mill

High Rolling Mill an overview ScienceDirect Topics

A twohigh rolling mill is assumed to be used with rolls of 250 mm diameter The elastic modulus of the roll material is taken to be 210 000 MPa and its Poisson's ratio is 03 The model, developed by Roychoudhury and Lenard (1984), reviewed above, is used in the computations As implied above, different models predict different magnitudes of Billet: Product obtained from further reduction by hot rolling (the crosssectional area is 40*40 mm 2) Slab: Slab is any hot rolled ingot with a crosssectional area is 100 cm 2 and width is > or equal to 2* thickness Cluster rolling mills are used for the high draft Typical arrangement of rollers for rolling mill: Continuous rolling mill:ROLLING(A Brief Guide To Rolling And Rolling Mills)2021年2月8日 Rolling of Steel Plates in a Plate Rolling Mill Plate steel is defined as a flat, asrolled or heat treated product of thickness of at least 5 mm and width of at least 1,200 mm Plate steel is widely used steel Rolling of Steel Plates in a Plate Rolling Mill –

rolling mill used machine for sale

Manufacturer: ECAI Type: LCG32 YOM: 2008 Machine Number: 70802002 ECAI LCG32 is a rolling mill with a radial force of 125 tonnes and an axial force of 90 tonnes It can roll rings with a maximum height of 500 mm, a maximum diameter of 2,500 mm and a maximum weight of 25 tonnes (these sizes are for standard steel)2019年10月1日 d b = 360 mm at the roll barrel An init ial section of d 0 = 28 mm shall be reduced to a [Show full abstract] mill stands are used, with 2‑roll, 3‑roll, and 4‑roll stands For each Roll Pass Design Methods for Three and Four Fives pursued a unique approach to use a similar process to stainless steel cold rolling We designed a robust monobloc DMS 20Hi EcoMill for thin GIGA steel with the following results: Steel thickness: 05 mm 25 mm Strip width: 800 mm 1,650 mm Production capacity: 180,000 tonnes per yearFives Group Fives Group 20Hi cold rolling mills

Roughing Mill an overview ScienceDirect Topics

Consider the hot rolling of a lowcarbon steel strip in a single stand roughing mill Let the entry thickness of the slab be 20 mm and its width to be 2000 mm Its resistance to deformation is taken to be 150 MPa It is reduced by 30% using work rolls of 800 mm diameter, rotating at 50 rpm2022年10月19日 The billet rolling mill is mainly used to supply square billet (50 × 50~240 × 240 mm), flat stock of strip mill, and tube stock of tube mill The three high bloomers are generally arranged by several three high mills in one or two rows, with a roll diameter of 500~750 mm This mill can roll small ingots weighing less than 15 tons into Billet Rolling Mill Hani Techroll diameter: 550 mmroll length: 1500 mmrolls drilled: Kernbohrung Nip adjustment: Hydraulisch total power requirement: 150 kWCondition used, refurbished, Specification Roll mill 550 x 1500 mm used roll diameter: 550 mm roll length: 1500 mm Variable friction ratio between rolls cored rolls with central chamber for water cooling nip used rubber machines for sale (417) on RESALEINFO

A Comparative Analysis of Forming Railway Axles in 3 and 4Roll

2020年7月10日 The rolls used in the two analyzed processes have different outside diameters: D = 500 mm (3roll method) and D = 300 mm (4roll method) Other parameters of the rolls are identical in both processes, ie, α = 25°, β = 30° and b = 20 mm The rolls are set askew to the axis of the workpiece at θ = 5° The correct shape of a rolled axle 2016年6月5日 Rolling is the most important metal forming process More than 95% of ferrous and nonferrous metals and alloys are processed to their usable shapes by rolling Usable shapes of rolled metals are plate, sheet, strip, foil, different sections like rail, beam, channel, angle, bar, rod, and seamless pipe, etc, as shown in Fig 11 and Fig 12Introduction to Rolling Process (Chapter 1) Principles and Used new Hot Rolling Mill for sale Top brands offers available now Buy sell used machines conveniently online International Categories 65 mm, Plate rolling machine 3 roll variable axis Brand Froriep Germany Year of make 1969 Maximum Capacity rolling mild steel 4000x65 mm / 3000 x 80 mm Hydraulic pistons bending power 750 Used Hot Rolling Mill for sale on Machineseeker

What is "Cold Rolling" Stainless Steel and Other Metals?

Cold rolling, unlike hot rolling such as with hot rolled steel, can only occur when a metal is below its recrystallization temperature Where hot rolling is performed using high temperatures, cold rolling is performed at room temperature Instead of heat, mechanical stress is used to change the structure of metal2021年1月18日 The socalled selective roll cooling is applied mainly for cold rolling mills to control the asymmetrical flatness deviations the strip width There are furthermore across applications for special castrolling mills for narrowgauge hot strip production Normally, two rows of nozzles are used in one header The row of nozzles directed toGENERAL ASPECTS OF ROLL COOLING FOR HOT2023年10月31日 6 High reversing cold rolling mill is the cold rolling production line with designed annual output of 200 thousand tons and adopts UCMtype singlestand mill It rolls pickled hot rolled coils into 1380mm 6 High Reversing Cold Rolling Mil

Hot rolling mills for aluminum SMS group GmbH

The ingot scalpers are installed upstream of the hot rolling mill They remove the oxide skin as well as any metallurgical impurities from the surface of the ingots Scalping the edges reduces the amount of trimming scrap generated in the subsequent hot rolling process and keeps the work rolls clean They achieve shifting distances of more 2021年8月16日 A series of cold rolling operations are to be used to reduce the thickness of a plate from 50 mm down to25 mm in a reversing twohigh mill The roll diameter = 700 mm and the coefficient of friction between rolls and work = 015 The specification is that the draft is to be equal on each pass Determine the minimum number of passes requiredBulk Deformation Processes Solved Problems2019年6月7日 There are hundreds of such mills in our country The length of roll body is between 100600 mm and the diameter of the roll is between 100300 mm Most of these rolling mills have uncoilers and coilers These mills are mainly used to produce narrow strips below 600 mm or flat rolled narrow strips with rolling speed ranging from 12 to 20m/sCold Rolling Methods of Cold Rolling Mill Hani Tech

Bar and wire rod mills SMS group GmbH

Highspeed rolling mills are designed to obtain superbquality wire rod – more precise than ever They process any kind of steel grade at a low rolling temperature Reliable of rolling wire rod from 45 to 27 mm diameter at a constant speed of 120 m/s (design 140 m/s), entry temperature of 750 °C, product tolerances up to ±010 on Ø 55 3" (76 mm) Rolling Mill Machine Jewelry Tools Flat Accessories: 1 Rolling Mill Machine (2 rollers assembled), 1 Handle, 1 Roller Adjustment Screw The Rolling Mill Machine is designed to meet the needs of Jewelers and metal smiths It is compact, economical, and costeffective Rollers are hardened approx 60 HRC for superior deformation Simond Store Rolling Mill Machine Simond Store2016年2月25日 If a mill rolls 80 % of the calendar year, that is 365 x 24 x 080 = 7008 hours If the mill rolls 800,000 tons per year, it runs at an average production rate of 11416 tons/hour If the PROCESS OF ROLLING MILLS LinkedIn

Forged Steel Roll Back Up Roll For Rolling Mill TINVO

2020年2月27日 Forged Steel Back Up Roll Definition The forged back up roll is a mill roll that supports the work roll and intermediate roll for the purpose of avoiding deflection of the work roll and affecting on the yield and quality of the plate and strip rolling mill This is the key function of back up roll to ensure the operation of the whole rolling mill The common 2017年6月18日 A series of cold rolling operations are to be used to reduce the thickness of a plate from 50mmdown to 25 mm in a reversing twohigh mill Roll diameter = 700 mm and coefficient of friction between rolls and work = 015 The specification is that the draft is to be equal on each passProblems in Metal Rolling PDF Scribd2022年3月15日 This rolling mill is capable of producing 15 to 16 mm thick strips depending steel grade by altering the gauge (gap between the rolls) setup in its online pass schedule design and control model 4450 examples from the Algoma rolling mill are used to evaluate each method PAM and VAF for the mill model and the proposed MSNS and Multistep networks for roll force prediction in hot strip rolling mill

Hot Strip Mill an overview ScienceDirect Topics

Analysing metal working processes G Engberg, L Karlsson, in Fundamentals of Metallurgy, 2005 1151 Hot rolling Mill data from the hot strip mill has been used to calculate the mean flow stress in each pass, assuming the material to be elastic – ideally plastic The roll force model used was a classical slab method with constant friction 2018年5月1日 Results of calculations and experimental studies of rolling torque in rolling mill 5000 Figures available via license: Creative Commons Attribution 30 Unported Content may be subject to copyright(PDF) Method of load calculation of electrical drives of rolling mills 2022年1月1日 A rolling mill machine's condition monitoring involves keeping a close eye on the performance of the roller bearings and detecting bearing faults until they cause any problems Acoustic emission is a nondestructive testing tool used in structural health control that is gaining interest in the diagnosis of bearing defectsCondition monitoring and fault detection in roller bearing used

Unit4 (Class10) Rolling

2016年7月4日 *3 high roll mill three rolls are used here *4 high roll mill four rolls are used here *Cluster roll mill a number of rolls are used in conjunction *Planetary roll mill rolls are arrangement in the form of planetary movement *Tandem roll mill continuous arrangement of rolls are used for continuous rolling *Sendizmer roll millsimilar A unique combination of low capital cost and product flexibility 29/116 Steckel mills are the proven solution for coil production up to 15 Mtpy and at the same time represent the most costeffective choice within the large hot rolling mill family Recent innovative solutions applied to modern Steckel mills make it possible to achieve high Products › Flat › Steckel Mills A unique combination ofRobust fine rolling mill with 800 mm roll width and 800 mm roll diameter, incl main drives, auxiliary drives, control cabinet and hydraulic unit for splitting In regularly maintained condition, rollers without riefen Available for an extra steel rolling used machine for sale

(PDF) Rolling Process Analysis of Working Rollers of Cold Rolling Mill

2020年10月1日 Diameter(mm) Length(mm) 635 1444 Table 4 Material performance parameters of working rollers Elastic modulus A 20high Sendzimir mill is widely used in cold rolling The deformation of 7,810 km Thread rolling machine FETTE R 40 (12 39 mm) Gewinderollkopf Fette 1980 used €5,500 Fixed price plus VAT Send inquiry Thread rolling machine make FETTE type R 40 Make # 818 Year of manufacture 1980 Technical data: Thread rolling range metric 12 39 mm thread rolling range inch 7/16 1 1/2" gr rolling thread length 500 mm Used Rolling Mills for sale on Machineseeker2013年5月30日 Fig 4 Roll configurations in rolling mills Twohigh mill roll configuration – This is the most commonly used rolling mill configuration In this configuration, there are two horizontally mounted rolls The rolling Basics of Rolling and Rolling Mills – IspatGuru

A Comparative Analysis of Forming Railway Axles in 3 and 4Roll

2020年7月10日 The currently biggest 2roll rolling mills of D461500 type have 1500 mm diameter rolls and make it possible to produce Ø 160 mm × 1300 mm parts In turn, the biggest flatwedge rolling mills, WRL20035TS, have 35 m long tools and make it possible to roll parts of up to Ø 200 mm × 1200 mm in size In effect, the CWR machines are not 2023年3月31日 The 5500 mm thick plate rolling mill studied in this paper adopts the bottom installation, as shown in Figure 2 and Figure 3, the HGC hydraulic cylinder is installed on the bottom of the frame, and above it is the lower support roll, the lower work roll, the upper work roll, and the upper work roll The roll gap of a rolling mill generally Biomimetics Free FullText Optimization Strategy of Rolling Mill TwoHigh: Generally, a 2HI mill is used for hot or cold breakdown and finishing of bar, sheet or strip A wide range of sizes with separating force capacities from 10,000 lbs (453 MT) to over 3,000,000 lbs (1360 MT) are available ThreeHigh: A 3HI mill is an economic milling solution for the breakdown of rod and ingot FourHigh: A 4HI mill may be used for finish Rolling Mills Metal Rolling Mill Machine Rolling Mill

(PDF) Wear of hot rolling mill rolls: an overview ResearchGate

1994年8月1日 tons of hot rolled steel per millimetre of machined roll diameter (t/mm), whereas typical flat rolls have "lives" about 5 10 320 10 3 t/mm blockondisc and laboratory hot rolling mill2020年6月1日 Abstract and Figures This work deals with the simulation model of multimachines system as cold rolling mill is considered as application Drivers of rolling system are a set of DC motors, which (PDF) Simulation Model of Cold Rolling Mill ResearchGate2020年1月3日 The rolling mill produces sections with diameters from 90 mm to 200 mm Traditional technology does not provide opportunity for rolling the sections with diameters of more than 200 mm In (PDF) 2020 Technology and Operation of a Hot Rolling Mill

High Rolling Mill an overview ScienceDirect Topics

A twohigh rolling mill is assumed to be used with rolls of 250 mm diameter The elastic modulus of the roll material is taken to be 210 000 MPa and its Poisson's ratio is 03 The model, developed by Roychoudhury and Lenard (1984), reviewed above, is used in the computations As implied above, different models predict different magnitudes of Billet: Product obtained from further reduction by hot rolling (the crosssectional area is 40*40 mm 2) Slab: Slab is any hot rolled ingot with a crosssectional area is 100 cm 2 and width is > or equal to 2* thickness Cluster rolling mills are used for the high draft Typical arrangement of rollers for rolling mill: Continuous rolling mill:ROLLING(A Brief Guide To Rolling And Rolling Mills)